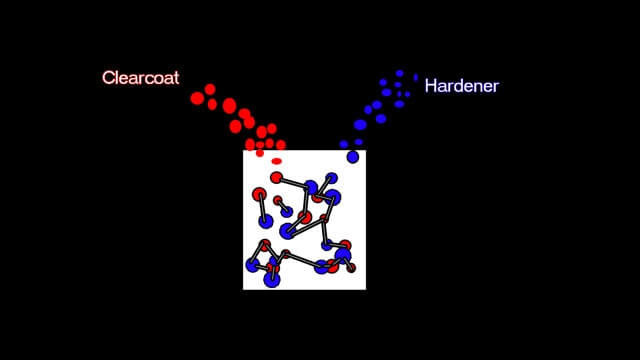

Basic Cross linking Explained

Cross Linking is used in many different parts of the auto body process. From the bumpers being manufacturer to the clear being applied, cross linking exists in some form or another to provide superior durability.

Cross linking in a basic sense is mixing A + B together to make a finished chain A-B-A-B-A-B-A-B….repeating to make one great big molecule. These products fall into what is know as thermosetting plastic materials. By mixing A & B together you end up with a completely different product with independent characteristics.

Bumpers are a great example of a cross linked product. Think of your typical plastic, you can heat it, melt it like a wax & shape it to your hearts content. With a thermosetting plastic there is another substance added to the plastic which creates a new product. The new product no longer has the same properties, you can no longer melt & shape it. Tires are the same way which is what makes these types of plastics difficult to recycle. Tires can be shredded to create something new, but never broken down to recreate a tire.

In the case on epoxies, it takes the cross link a step further. It produces more contact points for your cross links. So you could think of it as you mix A + B and end up with :

ABABABABAB

\ /

BABABABABA

/ \

ABABABABAB

This is a very, very simple explanation of it but that\’s the concept in it’s simplest form. The unique cross link produced by an epoxy gives it the strength and performance making it a top shelf product.