3M Mask Fit Test

3M Mask Fit Test

Today we had a 3M representative visit our shop to go over a few things and help us better protect ourselves against organic solvents and isocynates found in the paint we are spraying. I thought I would take a minute to share what he had to say.

First we went over basic charcoal mask inspections and testing. He started out by pointing out the valves on the inside and how important it is to verify the functionality of them. First you should ensure the valves are not torn or damaged in any way. You should find one in the middle for your exhalation and two on the sides from inhaling. The rubber should checked for kinks and the condition of it should not we excessively worn. Over time it can become softer and not seal as well as it should.

Next we placed the masks on and were asked to cover the exhale port on the outside with our hand, breath out and verify the mask starts to swell indicating a seal. Next we tested how effectively the mask was working. With our mask on we placed a container (like a big bucket) over our head and a very bitter solution was sprayed into the container to see if we could taste it. We were instructed to breath through our mouth and move our head to the side, up and down for about 3-4 minutes. Afterwards to verify the test we needed to have the bitter solution sprayed on our tongues to verify we could taste it.

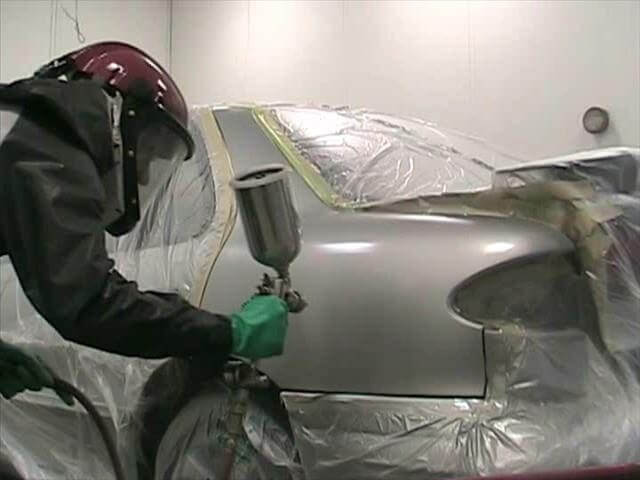

As most people know isocynates are not only breathed in but absorbed through our skin and eye sockets. After speaking with him today our painters are going to be switching to a fresh air mask / charcoal hybrid mask. This is the type we are looking at:

It is slightly different then the picture. It has an adapter that sits between the charcoal canister on both sides that supplies fresh air. It is a very lightweight, portable unit that still functions even when disconnected by filtering air though the charcoal cannister. I think this is a great design and an easy switch for guys currently using just a charcoal half mask.

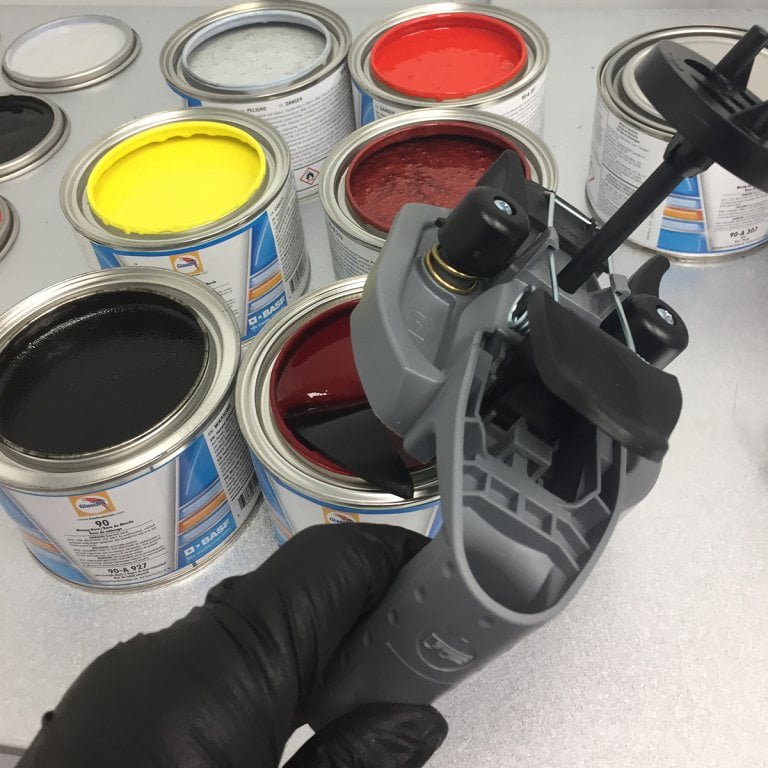

We are going to do some air quality checks on our compressed air and figure out whether we use the compressor or a separate fresh air supply. Either way I think it should be an easy switch far any painter and it is a good feeling to know your better protected against chemicals in this trade.

He did say that charcoal full face masks (non-fresh air) have proven to be very effective but the reason that so many regions specify a fresh air supply needs to be used for compliancy is because you cannot fully detect if your mask is working or if the canister needs changing. Since the only way to know exactly when your canister needs changed is by the smell of paint and solvents, you would have already been exposed to the chemicals by that point. His suggestion for us when using only charcoal was to change the carbon filters weekly to ensure they are always still functioning. Carbon filters have a chemical shelf life but can be shortened by constant use.