Mazda 46G Machine Grey Metallic

A new set of colors using a leafing aluminum flake has recently gained popularity in the refinishing community, with Mazda 46G, Machine Grey Metallic being one of the most sought-after shades. However, it’s worth noting that this is not the only color using this flake – Mercedes has used the same flake in their Alubeam Metallic for several years. Many manufacturers have developed special procedures for the application of this aluminum flake, so it’s important to follow their recommendations to achieve the best results.

46G is a multi-step translucent color that requires a specific ground coat to be applied and sometimes blended out before applying the flake. 46G requires a black groundcoat, which may be unusual for some technicians working with translucent colors. The top or mid coat contains a high amount of small, smooth aluminum flake, which needs to be oriented correctly for the best results.

In terms of prep procedure, most manufacturers recommend sanding with a finer grit than normal, such as P1000, to create an optimal surface for the flake. The black basecoat can be applied as either a basecoat or sealer, and most manufacturers provide similar recommendations for blending it out.

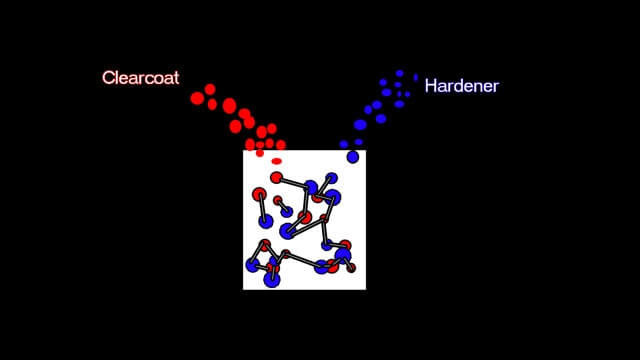

When it comes to the orientation coat and clear coat, there are varying recommendations from different manufacturers. Some suggest applying a clear orientation coat and then painting as normal, while others recommend using a 2-part clearcoat that needs to be dried and sanded back down flat.

The application of the flake itself also has some variations in recommendations, with some manufacturers suggesting a smaller tip size or drier application, while others suggest applying it like any other basecoat. It’s generally agreed that the effect or drop coat is key to creating a uniform, mottle-free look. Some companies suggest using an X pattern to achieve this, while others do not specify. It may also take a few more effect coats than normal to get the color looking right.

Finally, some manufacturers recommend applying a light coat of clear or grip coat to create a barrier before applying the next two coats, to prevent the flake from shifting and creating a blotchy look. Others do not make this recommendation. In general, it’s important to follow the specific guidelines for the aluminum flake color you are using, as the fine prep and effect coats are critical for achieving the desired results.